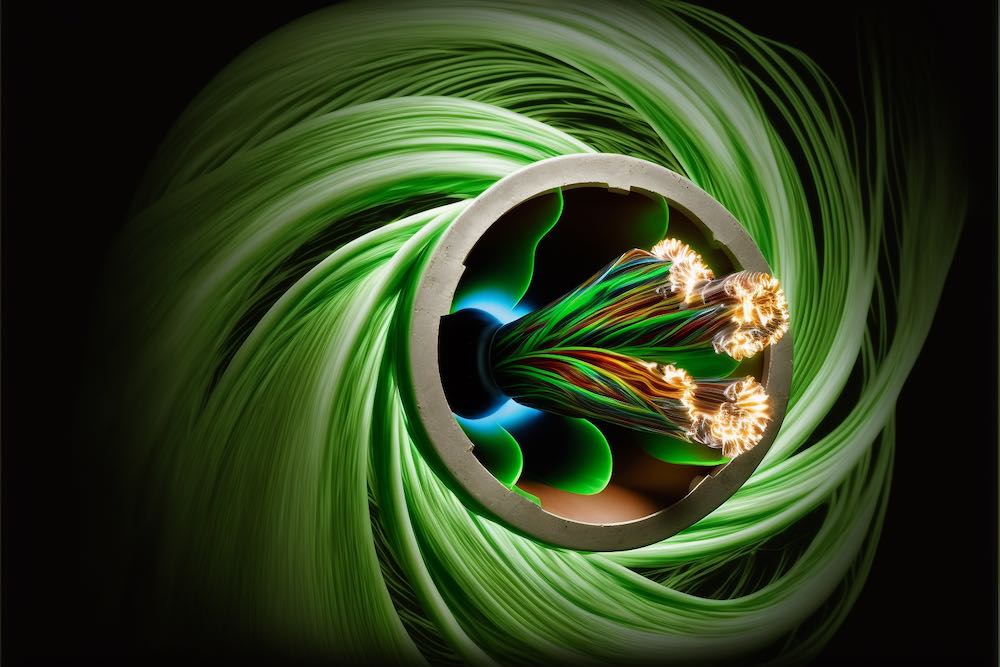

Innovation is part of our DNA

We are your leading Fiber Optics innovation partner. We are a unique international reknown company with a global footprint and are key high tech industry Solution Provider for various global partners. Let’s join forces from initial ideation phase to final product and solution implementation in the market to scale your business.